Redesign Transport Management System

About the company

Forto is a B2B logistics company based in Berlin, Germany, specializing in international freight forwarding. The company handles trade lanes primarily from Asia to EU and EU to Asia, with additional business on EU to America routes. Forto manages all modes of transport—truck, rail, and sea—and handles pre-carriage, main carriage, and on-carriage services for customers across the EU.

Role and responsibility

As Lead Product Designer, I led the redesign of Forto's internal Transport Management System (TMS), a critical tool used by the operations team to manage shipments, including booking, communication, and financial handling. This project started in early 2025 and is ongoing, focusing on transforming a fragmented system into a workflow-driven experience that supports operations teams in executing their daily tasks efficiently.

The problem

The TMS was built as a collection of disconnected pages with no clear user workflow. Operations managers had to navigate through scattered interfaces, knowing exactly where to find what they needed—a steep learning curve for new team members. The system didn't guide users on what to prioritize or how to complete specific tasks, leading to inefficiencies and critical errors.

Key pain points

No workflow structure: Pages were scattered with no logical flow or user journey resulting in:

- Financial impact: DEM/DET (Demurrage/Detention) costs due to missed deadlines and lack of timely communication

- Customer trust issues: Delayed responses and missed tasks damaged customer relationships

- Lack of guidance: System didn't indicate what to prioritize or how to execute tasks

- No origin vs destination segregation: All shipments were treated the same, regardless of their stage in the logistics process

- Missing assignment system: Shipment tasks could get missed without clear ownership

Before: Scattered pages with no workflow. After: Unified workflow-driven interface

Design approach

Discovery

To understand the operations team's needs, I conducted extensive user interviews and worked closely with operations managers across different regions. Our stakeholders included teams in Germany, China, and Vietnam, each with their own regional workflows and requirements. We started with Origin handling as our first focus area.

As milestone 1, coverage includes origin handling for shipments leaving EU. Initially, I partnered with 2 operations managers on a daily basis, which later expanded to 5 for broader feedback collection. This close collaboration was essential to build trust and understand the nuanced requirements of logistics operations.

Key findings

- Consistent milestones across regional variations: While different regions have different workflows and requirements, the core milestones remain consistent across all regions. This common milestone structure can be leveraged to create a unified workflow design that accommodates regional variations while maintaining a cohesive system.

- Operations teams needed a system that supports task execution: The existing system functioned as a checklist rather than actively supporting task completion and workflow management.

- Clear assignment and ownership were critical: Without explicit task assignment, shipment tasks could easily be missed, leading to operational failures.

- Timely communication with customers was essential: Delayed responses resulted in financial penalties from DEM/DET costs and damaged customer relationships.

- Lack of trust with TMS: Years of frustration and inefficiencies had eroded the operations team's confidence in the system.

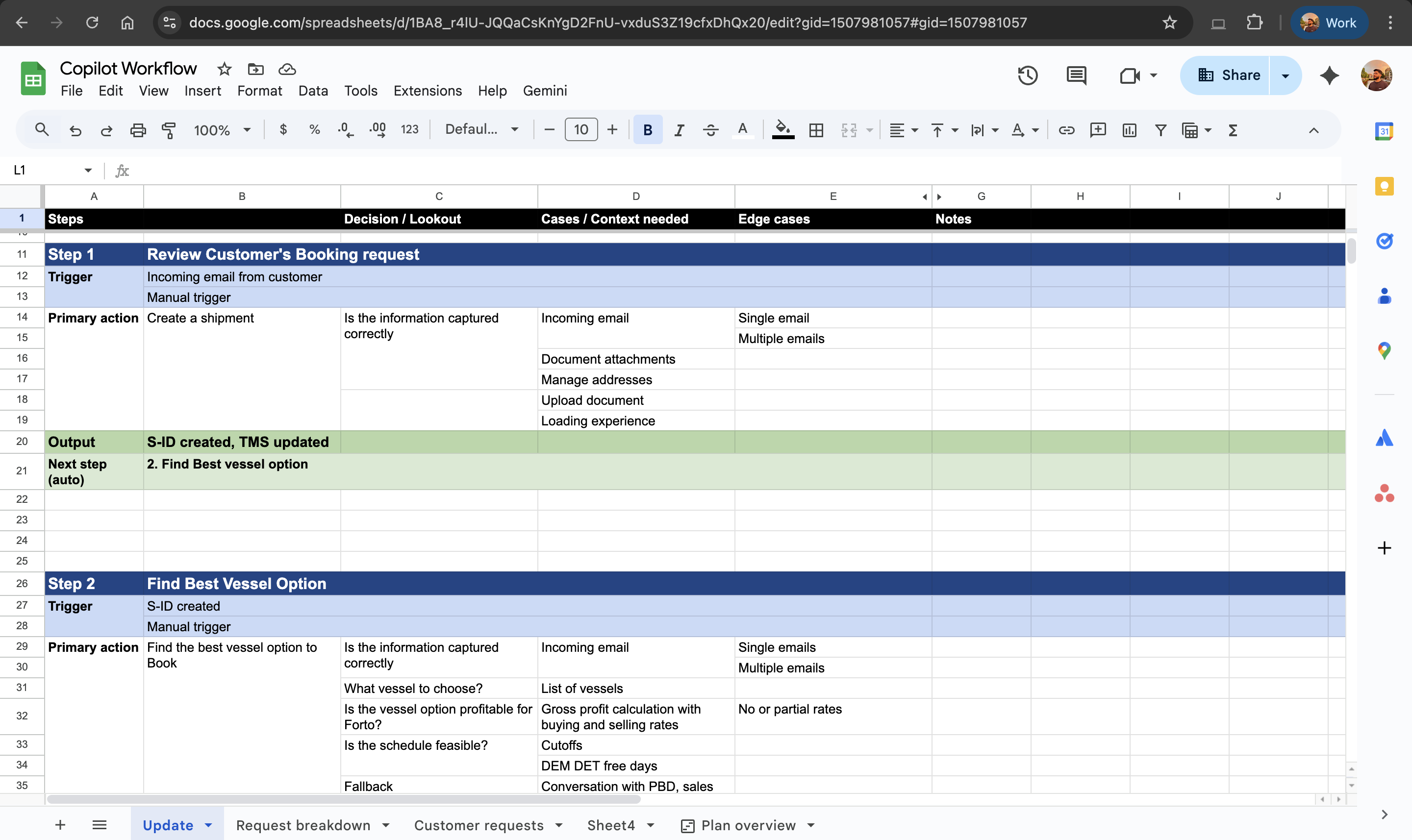

Mapping shipment lifecycle

We started by mapping the entire shipment handling flow at a high level, understanding the complete journey from booking request to vessel departure. Once we had a clear picture of the end-to-end process, we broke it down into smaller, manageable steps. Rather than redesigning the entire system at once, we took an iterative, step-by-step approach. We redesigned one shipment handling step at a time, ensuring each improvement was validated and adopted before moving to the next. This approach was crucial for building trust with the operations team and ensuring sustainable adoption.

User journey map: From booking request to vessel departure

Rapid prototyping with LLM tools

Initially, we used Figma as our tool for concept creation, but slowly moved to Cursor. We had to get engineers on board, but we also had the support of the EM and after initial iterations, the engineers also were excited with the pace. I leveraged Cursor with GitHub integration to accelerate the design and development process.

When a pain point was identified, I created a design proposal on a separate branch. Once validated with operations managers, the proposal was merged into production with developer support. This workflow enabled quick iteration cycles and immediate feedback loops, improving the iteration cycle from weeks to days.

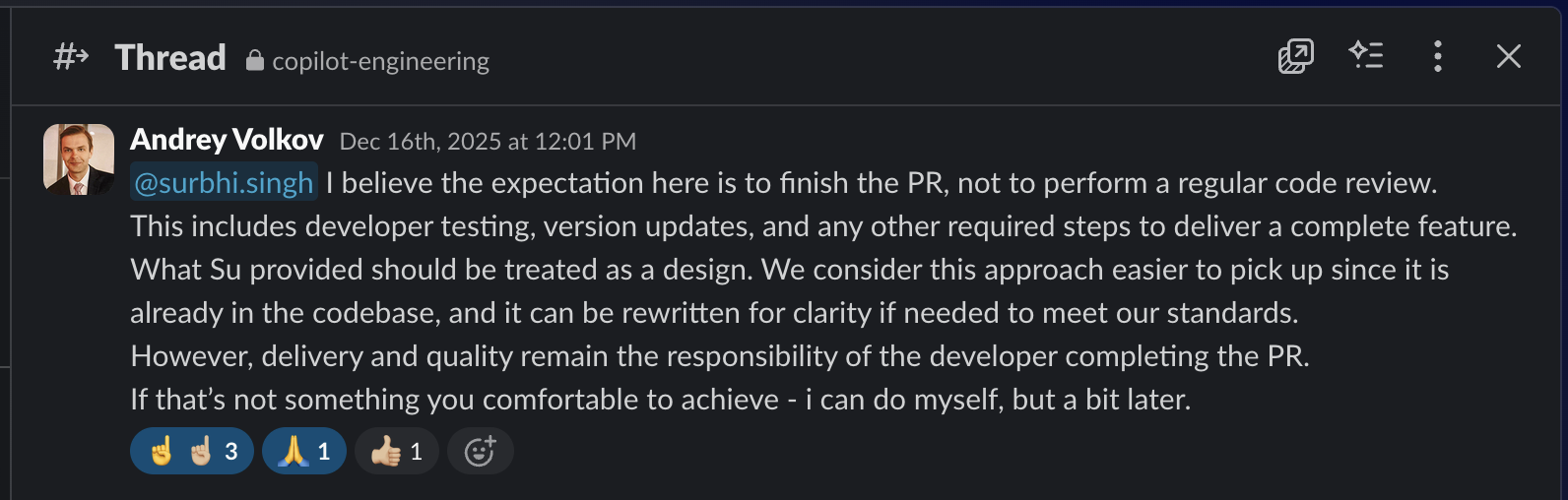

Slack message from Engineering Manager: Design proposals in codebase treated as design, with developers completing PRs for delivery and quality

Building relationships and alignment

One of the biggest challenges was building trust with operations managers who had lost confidence in the TMS. I worked closely with operations managers to establish and align on processes, ensuring the redesign addressed their real needs rather than assumptions. Regular feedback sessions once features went live helped refine the approach continuously.

The solution

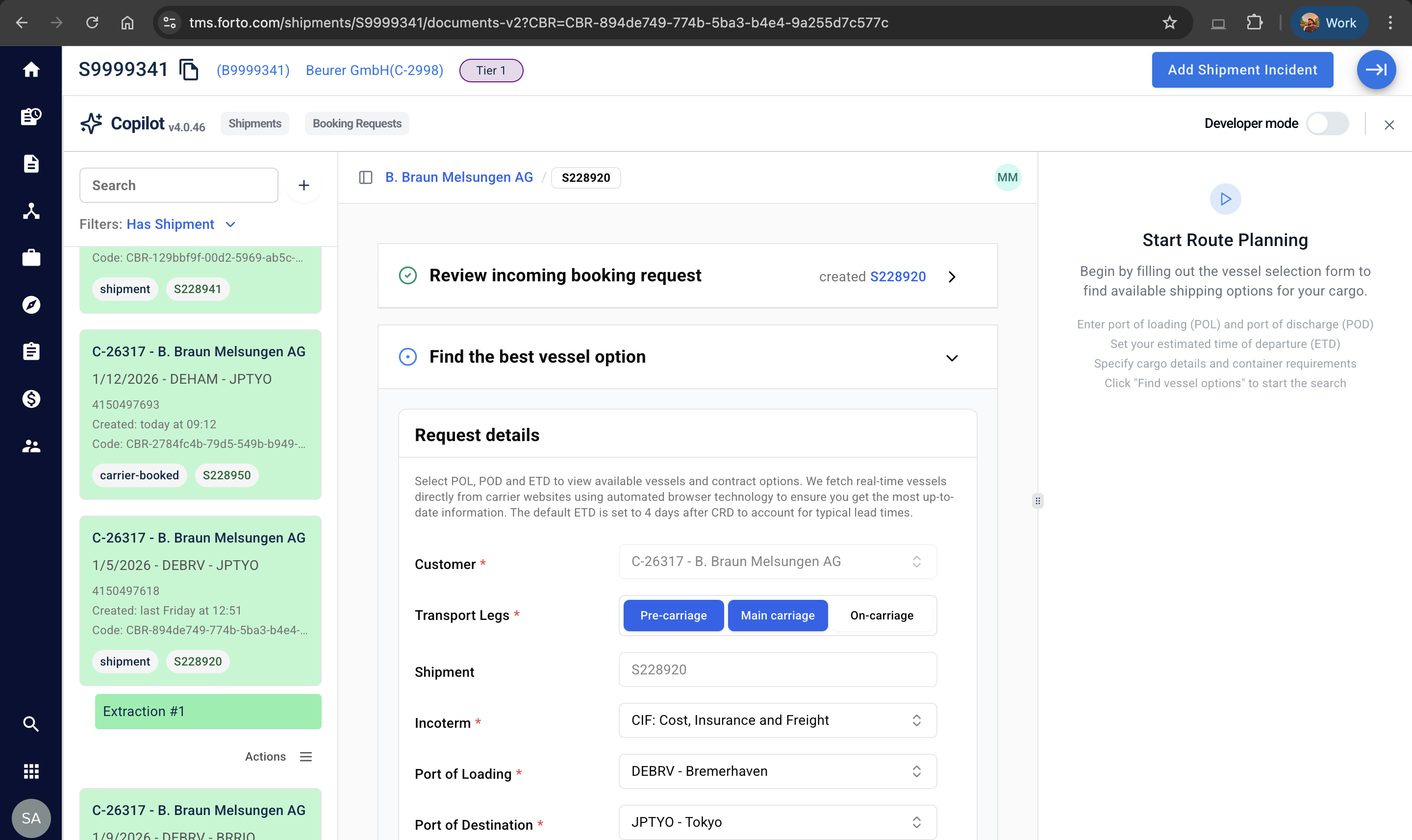

The redesigned TMS introduces a workflow-driven UI where every shipment follows a clear journey from booking request to documentation to vessel departure. The system now supports task execution rather than just serving as a checklist, with automatic assignment ensuring nothing falls through the cracks.

Workflow definition: Mapping the complete shipment lifecycle

Workflow UI

Every shipment now has a defined workflow that guides operations managers through each stage. The system clearly indicates what needs to be done, when, and by whom, eliminating the guesswork that plagued the previous version.

Origin vs destination handling

The workflow assigns tasks based on whether they are origin tasks or destination tasks. While these tasks can still be part of the same shipment, this approach provides clearer assignment and accountability, ensuring that the right team members are responsible for the appropriate stage of the shipment lifecycle.

Task prioritization (Work in Progress)

We're currently working on intelligent task prioritization to help operations managers focus on the most critical tasks first, further improving efficiency and reducing the risk of missed deadlines.

Prioritisation of tasks

Challenges and learnings

Building trust with operations

The operations team had lost trust in the TMS due to years of frustration. Rebuilding this trust required consistent communication, demonstrating value through quick wins, and ensuring that every change addressed real pain points rather than theoretical improvements.

Non-linear logistics processes

Logistics workflows are inherently complex and non-linear, with different regions following different processes. Aligning these diverse requirements while maintaining a cohesive system required extensive collaboration and flexibility in the design approach.

Ensuring team alignment

Once the vision was finalized, ensuring that all teams—especially developers—stuck to the approach was challenging. While developers had the best intentions, they didn't always think end-to-end about user workflows. Regular design reviews and clear documentation helped maintain consistency.

Feedback collection: Iterating based on real user input

Impact and outcomes

Adoption

The redesigned TMS has achieved high adoption rates among operations teams. The workflow-driven approach and clear task assignment have made the system intuitive and reliable.

Speed of execution

Task execution speed has dramatically improved, reducing from several days to seconds for many common operations. This improvement directly impacts customer satisfaction and reduces the risk of financial penalties from delays.

Reduced errors and costs

With automatic assignment and clear workflows, missed tasks have significantly decreased, leading to reduced DEM/DET costs and improved customer relationships. The system now supports operations teams in maintaining timely communication with customers.

Next steps

The redesign continues to evolve based on ongoing feedback from operations teams. Task prioritization features are currently in development, and we're continuously refining workflows to better support the diverse needs of different regions and trade lanes. The iterative approach ensures that each improvement builds on the previous one, creating a system that truly serves the operations team's needs.

This project demonstrates that successful product design in complex enterprise environments requires more than just UI improvements—it demands building relationships, understanding nuanced workflows, and taking an iterative approach that prioritizes adoption and real-world impact over theoretical perfection.